Energy Saving Industrial Ball Mill

Energy Efficiency Solutions Ball Mill WEG

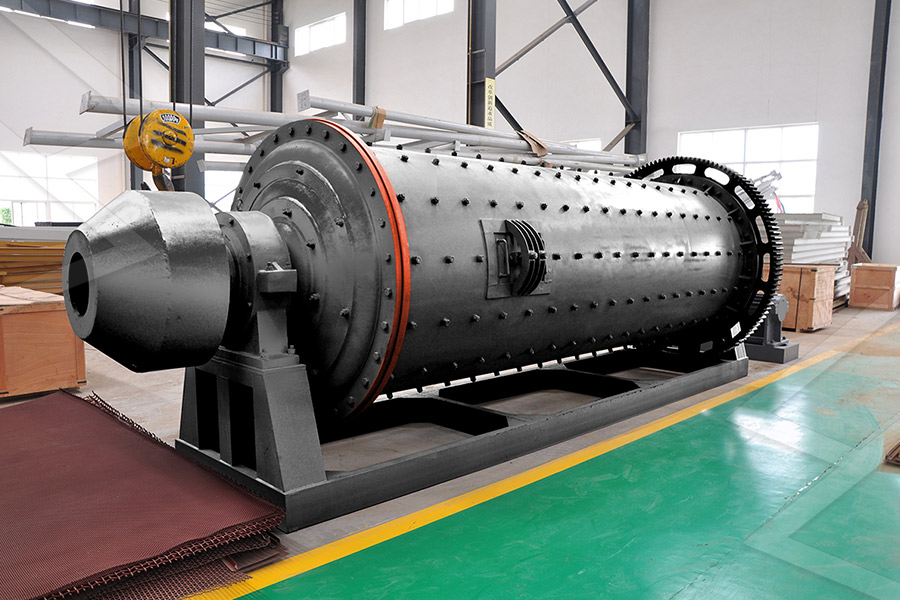

Ball Mills are widely used in the ceramic and mining industries, where the grinding process requires strict grain size control WEG developed an efficient solution for this application, 2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide BALL MILLS Ball mill optimisation Holzinger Consulting2024年11月1日 Examined the impact of media density on collision energy characteristics and liner wear This study investigates why ceramic balls achieve superior grinding performance Understanding the EnergySaving mechanism of ceramic balls 2024年11月1日 Examined the impact of media density on collision energy characteristics and liner wear This study investigates why ceramic balls achieve superior grinding performance Understanding the EnergySaving mechanism of ceramic balls

.jpg)

Enhancing the Grinding Efficiency of a Magnetite

2024年1月31日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particles This paper introduces a 2018年2月20日 In ball mills, energy savings vary from 10 per cent to 40 per cent compared to 25 mm media A regrind ball mill with a mix of small grinding media can be as energy effi cient as ENERGY SAVINGS AND TECHNOLOGY COMPARISON 2024年11月1日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency Understanding the EnergySaving mechanism of ceramic balls 2016年2月1日 Features of the specific energybased ball mill model include the use of an orespecific and sizedependent breakage function, whose parameters are independently A specific energybased ball mill model: From batch grinding

Energy Efficiency Analysis of Copper Ore Ball Mill

2021年2月26日 One method for increasing the energy efficiency of ball mills is to optimize their drive systems This article looks at two variants of drive systems with efficiencies higher than the already existing solutions2016年10月5日 Comparisons between different energyefficient grinding technologies and applications were presented for production of cement with energy savings Industrialscale data related to Horomill® and Polysius® EnergyEfficient Technologies in Cement 2024年1月31日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particles This paper introduces a Enhancing the Grinding Efficiency of a Magnetite 2016年10月5日 Comparisons between different energyefficient grinding technologies and applications were presented for production of cement with energy savings Industrialscale data related to Horomill® and Polysius® EnergyEfficient Technologies in Cement

Breaking down energy consumption in industrial

2017年1月17日 The grinding process in ball mills is notoriously known to be highly inefficient: only 1 to 2% of the inputted electrical energy serves for creating new surfaces2022年11月1日 Recent research contends that ceramic balls significantly reduce energy consumption in industrial tumbling mills In this work, the binary media method is proposed to enhance ceramic ball grinding performance Specifically, when feed ore hardness is high and the ceramic ball grinding effect on coarse minerals degrades, a certain proportion of steel balls Can ceramic balls and steel balls be combined in an industrial 2023年11月21日 vides a reference for the subsequent research on energy saving and consumption reduction in ball milling op erations The optimal grinding parameters were determined to be grinding concentration Energy conservation and consumption reduction in 2024年11月1日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particlesUnderstanding the EnergySaving mechanism of ceramic balls

.jpg)

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) 2020年2月26日 Owing to the lack of effective energy consumption models of ball mills in the ceramic industry, a calculation model to forecast energy consumption of ceramic ball mills during the grinding process Calculation method and its application for energy consumption of ball 2021年10月27日 Henan Yuhui Mining Machinery Co, Ltd is located in Zhengzhou city in central plains, which adjoins to ancient millennium Shaolin Temple (Kongfu Origin) to the south, and Yellow River to the north With Kailuo highway and Longhai railway, it owns convenient transportation and pleasant scenery Established in the 1970s, Henan Yuhui Mining Machinery Ball Mill,Cone Ball Mills,Cement Ball Mill,EnergySaving Ball Mill,Ball The energysaving industrial ball mill addresses these concerns by reducing energy consumption by up to 30% compared to traditional ball mills This substantial energy savings translates to lower carbon emissions and a more sustainable mining process China EnergySaving Industrial Ball Mill – stone cruxder

.jpg)

Attritor Ball Mill Superfine Grinding Stirred Ball

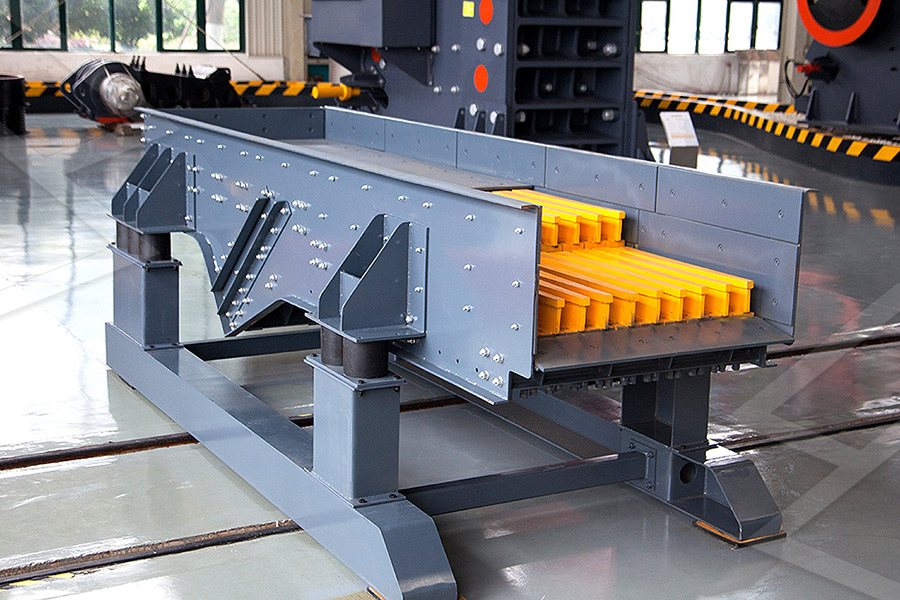

Attritor ball mill also called stirred ball mill, is a kind of ultrafine grinding equipment with high output and energy saving With the development of science and technology, there are more and more applications of ultrafine powders in 2015年7月3日 An energysaving ball mill is an efficient tool for grinding many materials into fine powder after they have been broken into certain sizes It is widely used in the chemical industry, new building materials, silicate products, fireproof materials, fertilizer industry, black and nonferrous metal processing, as well as glassceramics industry, It does dry or wet grinding for all Energysaving Ball Mill Introduction Skew Rolling Mill2018年2月20日 In ball mills, energy savings vary from 10 per cent to 40 per cent compared to 25 mm media A regrind ball mill with a mix of small grinding media Bazin (2008a) for two industrial ball mills The speci fi c breakage rate of Millpebs are higher than theENERGY SAVINGS AND TECHNOLOGY COMPARISON 2018年2月20日 Table 1: Millpebs performance results in industrial fine grinding mills Case No Ore Type Technology Application Bond Ball Size Power Savings Increase TPH Finer Grind 2002 Fe Ball Mill Regrind 26 mm Same Same Yes 2004 CuPb Ball Mill Regrind 5 mm 10% Same +56% 33% Same Yes 1 CuPbZn Ball Mill Secondary 8 mm 44% Same SameEnergy Savings and Improved Recovery with Small

.jpg)

Energy Saving Ball Mill Hongji Mine Machinery

2024年6月5日 By adjusting the gradation of the steel balls, the size and amount of the discharge fineness can be changed The highefficiency and energysaving ball mills produced by our company are all supported by rolling bearings instead of bearing bushes and sliding bearings Compared with the coaxial pad sliding beaning supported energy saving is 2030%2017年1月1日 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single stage SAG mill These scats are non spherical ball fragments resulting from uneven wear of balls (PDF) Performance optimization of an industrial ball mill for 2022年4月1日 In Figure 11b, when compared w the 25% charge volume of 12 × 12 mm cylpebs, it only demands that the ratio of the m of ceramic balls to cylpebs be 077:1, and a charge volume larger than 385% (1 The first attempt of applying ceramic balls in industrial tumbling mill 2024年10月21日 The EnergySaving Overflow Ball Mill market is characterized by a competitive landscape featuring several key players, including SBM, Joyal Crusher, TMAX, SIEHE Industry, STOCK, and XinhaiThe EnergySaving Overflow Ball Mill Market: Refracting

Energy conservation and consumption reduction in grinding

2023年11月1日 The research and development of stirring mills abroad began in the 1940s, and the technology of stirring mills developed rapidly in the 1960s, while the development of domestic stirring mills started in the early 1970sAfter years of development, stirring mills were developed into a wide variety of grinding equipment with various types and models, which were gradually 2021年3月23日 New ball mill drive system with the prototype energysaving SMH motor [37] Startup of the LSPMSM SMH1732T motor with a filled ball mill after two hours of downtime: (a) active power, (b Energy Efficiency Analysis of Copper Ore Ball Mill Drive 2021年1月1日 To demonstrate the importance of industrial energy savings from a regional viewpoint, the European Council emphasizes to reduce projections of primary energy consumptions in 2020 by 20% [20] The energy monitoring system successfully identified potential energysaving opportunities from a poorly maintained ball mill unit Teng et al [75]Recent advances on industrial datadriven energy savings: Digital twins What is Energy Saving Factory Price Ball Mill Mining Industrial Ball Mill, ball mill manufacturers suppliers on Video Channel of MadeinChina Home Video Channel What is Energy Saving Factory Price Ball Mill Mining Industrial Ball Mill Ball Mill US$6,4500015,00000 / Set View What is Energy Saving Factory Price Ball Mill Mining Industrial Ball Mill

Energy Efficiency Solutions Ball Mill WEG

Ball Mills are widely used in the ceramic and mining industries, where the grinding process requires strict grain size control WEG developed an efficient solution for this applic2024年7月4日 The global Energy Saving Ball Mill market was valued at US$ million in 2023 and is anticipated to reach US$ million by 2030, witnessing a CAGR of % during the forecast period 20242030Energy [20242030] Energy Saving Ball Mill Market Demand, Growth 2024年10月15日 The Latest Study Published by HTF MI Research on the "Energy Saving Ball Mill Market’’ evaluates market size, trend and forecast to 2030 The Energy Saving Ball Mill market study includes Energy Saving Ball Mill Market Demonstrates A Spectacular 2022年11月21日 Industrial Solutions Grinding and drying for a wealth of applications Our customers not only benefit from the decades of experience we have gained through successfully commissioning more than 2,200 ball mills, but also from our comprehensive scope of services, Costeffective, reliable and energysaving: with its highperformance range of Industrial Solutions polysius ball mills ThyssenKrupp

What Is An Industrial Ball Mill In The Food Industry

2023年9月8日 The main structure of the ball mill includes a solid cylinder, which contains grinding balls of different materials and sizes The motor and transmission system is used to drive the rotation of the cylinder, while the feeding and discharging system is responsible for the introduction of raw materials and the discharge of finished products2022年11月1日 The secondary ball mill can increase the surface area by reducing the diameter of steel balls to enhance the abrasion Industrial application results show that after the abrasion of the secondary Can ceramic balls and steel balls be combined in an industrial 2024年8月23日 An energysaving ball mill is a kind of equipment specially used for grinding ore, stone, or other materials Compared with traditional ball mills, energysaving ball mill reduces energy consumption and improve grinding efficiency by optimizing design and using a more efficient energy transmission systemEnergysaving Ball Mill VS Cement Ball Mill JXSC MineralEnergy Saving Ball Mill; Ball Mill Parts Menu Toggle Ball Mill Grinding Media; Ball Mill Liner; Ball Mill Trunnion; Ball Mill Trunnion Bearing; Ball Mill Pinion; Ball mill grinders are widely used in the cement industry, beneficiation industry, refractory industry, and other fields They can handle more than 200 kinds of nonmetallic ores Ball Mill Application – Industrial Application Of Ball Mill

.png)

Enhancing the Grinding Efficiency of a Magnetite

2024年1月31日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particles This paper introduces a 2016年10月5日 Comparisons between different energyefficient grinding technologies and applications were presented for production of cement with energy savings Industrialscale data related to Horomill® and Polysius® EnergyEfficient Technologies in Cement 2017年1月17日 The grinding process in ball mills is notoriously known to be highly inefficient: only 1 to 2% of the inputted electrical energy serves for creating new surfacesBreaking down energy consumption in industrial 2022年11月1日 Recent research contends that ceramic balls significantly reduce energy consumption in industrial tumbling mills In this work, the binary media method is proposed to enhance ceramic ball grinding performance Specifically, when feed ore hardness is high and the ceramic ball grinding effect on coarse minerals degrades, a certain proportion of steel balls Can ceramic balls and steel balls be combined in an industrial

Energy conservation and consumption reduction in

2023年11月21日 vides a reference for the subsequent research on energy saving and consumption reduction in ball milling op erations The optimal grinding parameters were determined to be grinding concentration 2024年11月1日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particlesUnderstanding the EnergySaving mechanism of ceramic balls 2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) (PDF) Grinding in Ball Mills: Modeling and Process Control2020年2月26日 Owing to the lack of effective energy consumption models of ball mills in the ceramic industry, a calculation model to forecast energy consumption of ceramic ball mills during the grinding process Calculation method and its application for energy consumption of ball

.jpg)

Ball Mill,Cone Ball Mills,Cement Ball Mill,EnergySaving Ball Mill,Ball

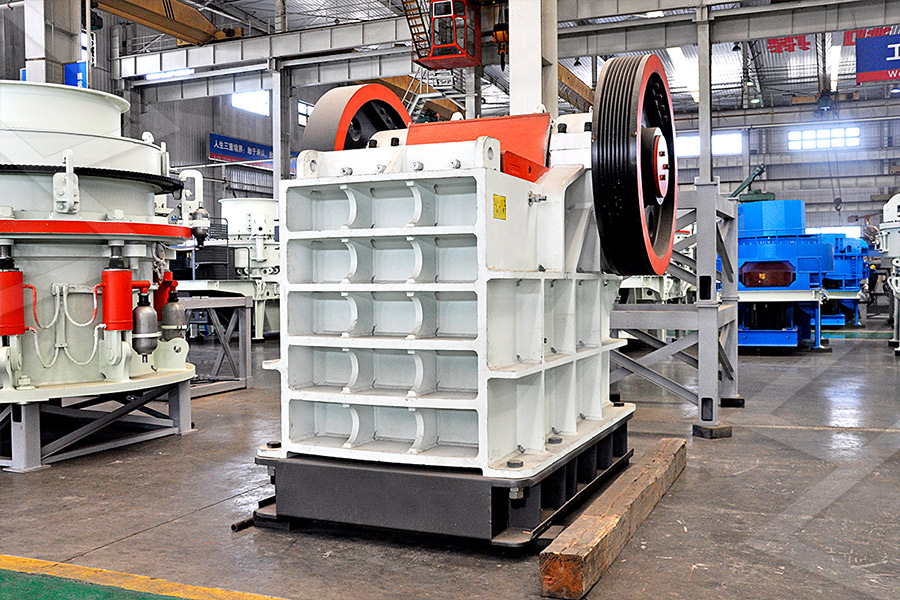

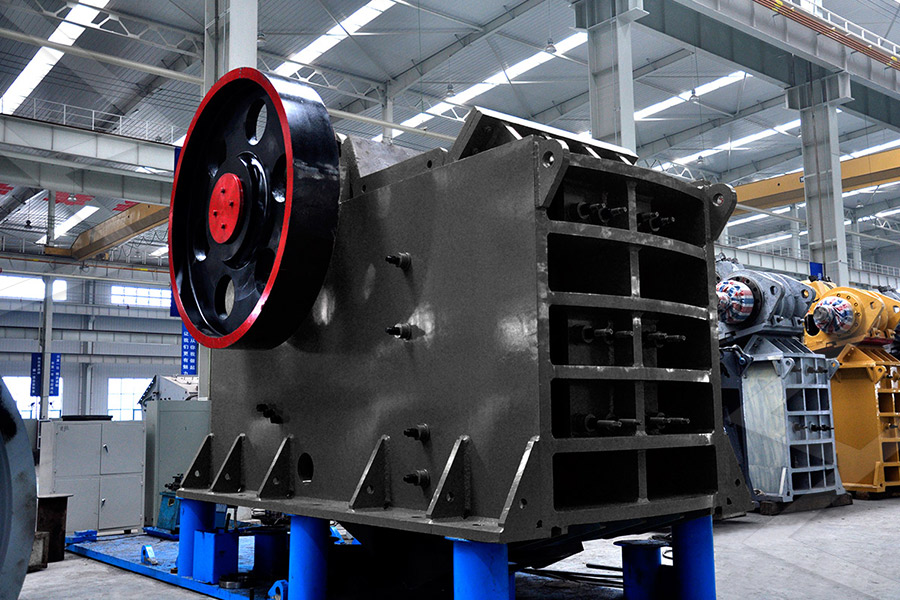

2021年10月27日 Henan Yuhui Mining Machinery Co, Ltd is located in Zhengzhou city in central plains, which adjoins to ancient millennium Shaolin Temple (Kongfu Origin) to the south, and Yellow River to the north With Kailuo highway and Longhai railway, it owns convenient transportation and pleasant scenery Established in the 1970s, Henan Yuhui Mining Machinery The energysaving industrial ball mill addresses these concerns by reducing energy consumption by up to 30% compared to traditional ball mills This substantial energy savings translates to lower carbon emissions and a more sustainable mining process China EnergySaving Industrial Ball Mill – stone cruxder