Lime Calination Project

Decarbonising the lime industry: Stateoftheart

2022年10月1日 This technology, exploiting the separation of the combustion and calcination reactions, has been investigated in the Low Emissions Intensity Lime and Cement (LEILAC) The LEILAC (Low Emissions Intensity Lime And Cement) project will pilot a breakthrough technology that aims to enable the cement and lime industries to capture the CO2 emissions emitted from the raw limestone as it is processed, Low Emissions Intensity Lime and Cement2023年6月1日 Steam calcination delivers benefits owing to the lower reaction temperature in steam A process to achieve carbon capture from limestone calcination in a steam atmosphere Steam calcination of lime for CO2 capture ScienceDirectLime is one of the most widely used and cheapest alkalizing agents employed worldwide It is often applied in chemical processes in a slaked or calcium hydroxide or slurry form The term Lime Calcination SpringerLink

Natural and enhanced carbonation of lime in its

2021年10月4日 Lime is a product derived from the thermal decomposition of limestone (mainly calcium carbonate, CaCO 3) into quicklime (CaO) and carbon dioxide (CO 2), also called calcination Controlled reaction with water is used 2023年6月12日 Limerelated products are obtained from the calcination of limestone —mainly calcium carbonate (CaCO 3)— at high temperature (900–1200 °C) The calcination reaction is Negative CO2 emissions in the lime production using an 2020年10月16日 Here, a novel lime calcination system with carrier gas (CO 2) heating and air cooling is proposed to avoid the mixing problem of the CO 2 and the flue gas This system consists of a new shaft kiln with four processing Novel Lime Calcination System for CO ACS 4 天之前 In the €21M LEILAC project, a new method of calcining limestone is being developed Instead of mixing the limestone with the fuel and air, it is segregated and the gas streams kept separate This is known as direct LEILAC: Cheap, efficient carbon capture for the

.jpg)

Effect of Steam Injection during Carbonation on

2022年1月6日 The CaL process relies on the multicycle carbonation/calcination of CaO, which can be derived from calcination of widely available, cheap, and nontoxic natural limestone (CaCO3) This work explores the effect on the 2012年11月17日 Lime is the high temperature product of the calcinations of limestone Lime is manufacture in various types of kiln by one of the following reactions; CaCO 3 + heat CO 2 + CaO ( high calcium lime) CaCO 3MgCO 3 + heat 2CO 2 + CaOMgO ( dolomite) The heart of a lime plant is the kiln There are various types of kilnFUNDAMENTAL APPROACH TO THE DESIGN OF 2021年1月1日 Lime and Cement”) projects (Hills et al, 2017; Hodgeson et al, 2018) that received nearly EUR 30 million in funding from the EU to build a prototype calcination furnace that promises to (PDF) Calcination ResearchGate2020年11月29日 Lime (CaO) is one of the most important industrial chemical used for various purposes, eg, production of soda ash (by Solvay process); for making pulp and paper; for metallurgical processes, eg, making of iron and steel; for construction purposes; for soil conditioning in agriculture; for sugar refining; for environment control to absorb oxides of Refractories for Lime Calcination SpringerLink

RealTime Lime Quality Control through Process

2021年8月21日 for lime quality control using datadriven machine learning approach Currently in lime plant at Tata Steel, lime produced at the end goes to the laboratory (Lab) for testing its quality This testing process takes additional 24 hrs to know the quality of lime, which creates a lag in controlling the future lime quality during the processShapoorji Pallonji EPC executed A Lime Dolomite Calcination Plant of RMLIII in collaboration with our technology provider Maerz, Switzerland under 7 MTPA expansion of Bhilai Steel Plant by Steel Authority of India Ltd (SAIL) in 2022 We are a diversified business conglomerate with clients in over 50 countries, delivering challenging Lime and Dolomite Calcination Plant at SAIL Bhilai, 年8月31日 The EU28 total lime demand in 2017 was estimated at about 20 million tons, out of which about 40% are consumed in the iron and steel industry(PDF) Management of Lime in Steel ResearchGate2024年1月1日 The cement production industry accounts for up to 15 % of the total industrial energy consumption and produces approximately 5 % of the total anthropogenic CO 2 emissions (IEA, 2019)The basic chemistry of cement production starts with the calcination of limestone (CaCO 3) that produces calcium oxide (CaO) and carbon dioxide (CO 2), followed by the Reducing carbon emissions in cement production through

CB05 Sustainable CPC Production at the Vizag Calciner

2021年3月13日 TRAVAUX 49, Proceedings of the 38th International ICSOBA Conference, 16 – 18 November 2020 527 Figure 2 Pyroscrubber and Waste Heat Recovery Boiler Figure 3 SO2 Scrubber and Baghouse 21 SO2 Scrubbing and Byproduct Lime Use The plant uses dry scrubbing technology and requires continuous injection of hydrated lime2020年12月3日 Oona Katajisto COREOona Katajisto CORE2023年10月5日 LIME CALCINATION PLANT Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much more If you need any customized project report and BANKABLE project reports as per your requirement, Click here to Project Report on LIME CALCINATION PLANTThe 90 data of kaffir lime oil were used in this project from high to low quality The abundance (%) of significant chemical compounds will act as the input and high or low quality as an output The 90 data will be divided into two sets: training and testing data sets with a ratio of 8:2 The radial basis function (RBF) optimization kernel RealTime Lime Quality Control through Process Automation

Project Report on Lime Calcination Plant Manufacturing

2023年10月15日 Lime Calcination Plant Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much more If you need any customized project report and BANKABLE project reports as per your requirement, Click here to 2023年11月26日 We treat the accurate simulation of the calcination reaction in particles, where the particles are large and, thus, the innerparticle processes must be resolved Because these processes need to be described with coupled partial differential equations that must be solved numerically, the computation times for a single particle are too high for use in simulations that [231115279] A reduced model for particle calcination for A good quality lime has also an impact on the refractory life and productivity in steelmaking [1] Lime is produced from lime stone having at least 50% calcium carbonate and various impurities [4] Quality of the calcinedlime mainly measured in terms of the availability of calcium oxide (CaO%) contained by it as shown in Fig 1RealTime LimeStorage Tracking Model in SteelMaking Plant2021年3月3日 Cement is produced by a hightemperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3)The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the limitation of several undesirable Cement SpringerLink

.jpg)

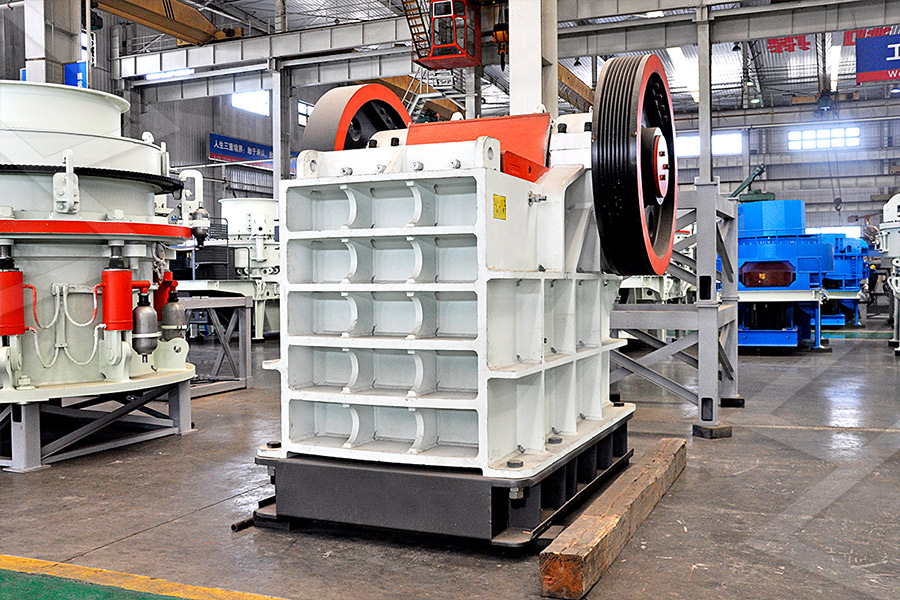

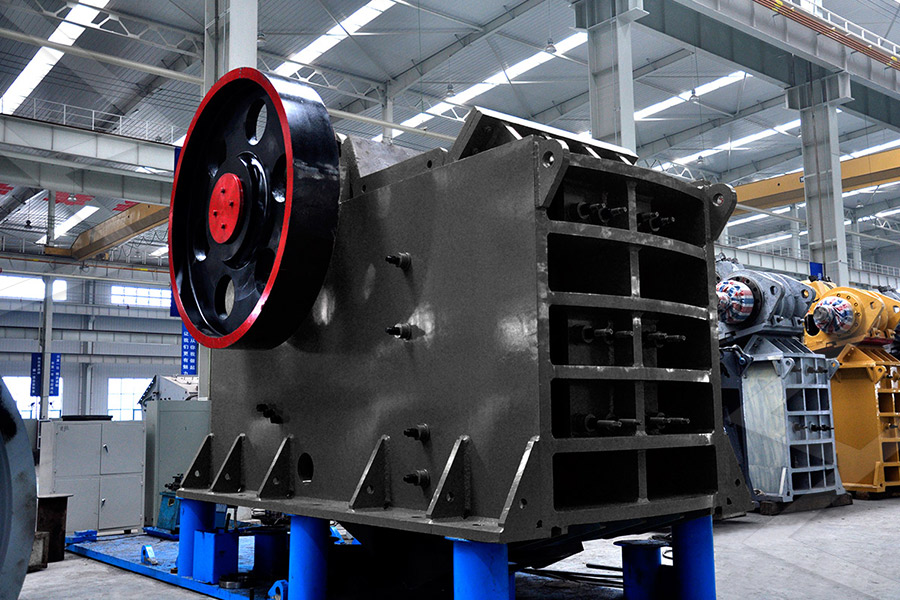

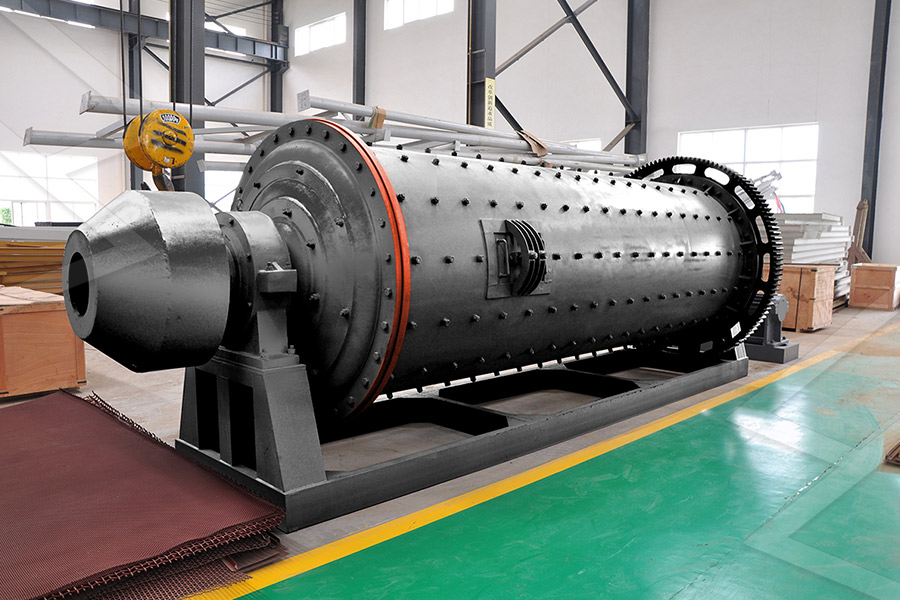

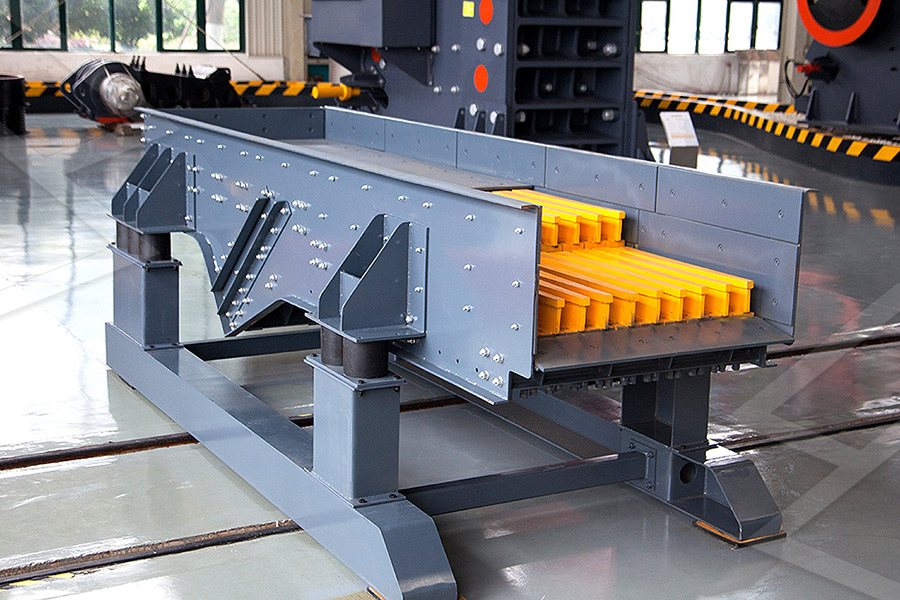

Cement Clinker Calcination in Cement Production Process

Raw Materials Crushing, Storing and Grinding Clinker calcination is the most crucial part of the whole process of cement manufacturing At this stage, ground raw materials will be sent into the cement kiln and be heated at a high temperature to produce chemical reactions with each other, eventually forming clinker In addition, clinkers that just complete the calcination will have a 2023年6月26日 Lime is the most important flux used in the LD steel making process The development of LD Process, calls for stringent control on the quality and a steady supply of Lime Tata Steel Lime Plant has 9 Kilns Limestone is sourced from Jaisalmer, Dubai, Oman Fujairah and Vietnam Limestone reach in Wagons from source and unloaded in TipplerSimulate and Optimize the Utilization of Resources in a 2024年1月30日 Calcination process is also used in the manufacture of quick lime from limestone The ore is disposed of moisture, organic content, and volatile contaminants including sulfur dioxide and carbon dioxide It increases porousness Carbon dioxide and metal oxides are produced during the breakdown of carbonate ores Calcination ProcessCalcination: Definition, Process, Examples, and Applications5 天之前 Lime Platform Customizations limeproject¶ limeproject scaffolds, manages, and deploys Lime CRM projects and customizations It can also create and run your local development environmentlimeproject Lime CRM Platform Documentation Lime

Clay Calcining Technologies FCT Combustion

Eight of these plants were brownfield, and 4 were greenfield projects With proven experience in this growing industry, we have the necessary experience to evaluate and suggest the most suitable production method for each individual project Published in ZKG Cement Lime Gypsum, issue 4/2021 Download article ‘Calcined clay colour control The LIME project supports the European Commission’s initiative Employers together for integration because it believes that the successful integration of third country nationals in the EU labour market, not only improves its functioning, performance and fiscal sustainability, but it is also an opportunity for our societies Employers can join the initiative by filling in this form and Resources LIME Project必应词典为您提供calcination的释义,美[ˌkælsɪ'neɪʃən],英[ˌkælsɪ'neɪʃən],n 【化】煅烧;(石灰的)烧成;【冶】氟化法;烧矿法; 网络释义: 锻烧;煆烧;焙烧;calcination 词典2017年8月23日 14 lime calcination gupta sudhir kumar, anushuya ramakrishnan, and yungtse hung contents introduction the chemical reactions kinetics of calcination properties of limestones and their calcines factors affecting lime calcination calcination of industrial solid wastes carbon dioxide emissions from lime calcination solar lime calcination conclusions nomenclature Gupta Sudhir Kumar, Anushuya Ramakrishnan, and Yung

.jpg)

LIME Project – Labour Integration for Migrants Employment

El proyecto LIME y el papel del cluster para la inclusión socioeconómica de los migrantes; 13 mayo 2019 Roma El Segundo Focus Group del Proyecto LIME; 7 mayo 2019 Roma LIME en acción: el primer Focus Group; 5 marzo 2019 Roma Proyecto LIME: (Labour Integration for Migrants Employment) integración laboral para el empleo de migrantes– Empezamos!Calcium oxide (CaO) is lime, which is produced through calcination of limestone including calcined limestone, ground limestone and hydrated limestone Production of lime is a complex industrial process and delivers two product forms quicklime and hydrated lime Lime is an important element in civil engineering and construction materialsCalcined Lime, Lime Calcination Entrepreneur India2021年2月28日 The EU28 total lime demand in 2017 was estimated at about 20 million tons, out of which about 40% are consumed in the iron and steel industryRealTime LimeStorage Tracking Model in SteelMaking 2021年12月20日 facturing of lime and magnesia, the clay rock may not need significant crushing prior to calcination 283 Expanded clay manufacturing plants Expanded clay, which is usually produced in northernClay calcination technology: stateoftheart review by the

KAKEN — Research Projects ADVANCED APPLICATION

1 Conducting coating of CaCO3Ag coated calcite was obtained by calination of Ag2CO3 coated calcite prepared by ion exchange method from AgNO3 aqueous solution with the suspension of calcite particles The coating on calcite was most uniform by calcination at 400500゚C of the particles prepared at 40゚C,under [AgNO3]=18*10^M and suspension of 2023年10月2日 The impact of the calcination temperature and grinding time on the mechanical properties and durability of limestonecalcined clay concrete (LC3) is crucial In this research, calcined clay was produced within the temperature range of 700 °C to 900 °C, and the grinding time varied from 15 to 120 min This study examines compressive strength and chloride Investigating the Calcination Temperature and Grinding Calix joined with key industry academic partners to develop Low Emissions Intensity Lime And Cement (Leilac) 2018 Calix listed on the ASX Calix announced as partner in sustainable fuels project Calix confirmed as a partner in the GermanAustralian Hydrogen Innovation Technology Incubator (HyGATE) sustainable fuels initiative About Calix2012年11月17日 Lime is the high temperature product of the calcinations of limestone Lime is manufacture in various types of kiln by one of the following reactions; CaCO 3 + heat CO 2 + CaO ( high calcium lime) CaCO 3MgCO 3 + heat 2CO 2 + CaOMgO ( dolomite) The heart of a lime plant is the kiln There are various types of kilnFUNDAMENTAL APPROACH TO THE DESIGN OF

.jpg)

(PDF) Calcination ResearchGate

2021年1月1日 Lime and Cement”) projects (Hills et al, 2017; Hodgeson et al, 2018) that received nearly EUR 30 million in funding from the EU to build a prototype calcination furnace that promises to 2020年11月29日 Lime (CaO) is one of the most important industrial chemical used for various purposes, eg, production of soda ash (by Solvay process); for making pulp and paper; for metallurgical processes, eg, making of iron and steel; for construction purposes; for soil conditioning in agriculture; for sugar refining; for environment control to absorb oxides of Refractories for Lime Calcination SpringerLink2021年8月21日 for lime quality control using datadriven machine learning approach Currently in lime plant at Tata Steel, lime produced at the end goes to the laboratory (Lab) for testing its quality This testing process takes additional 24 hrs to know the quality of lime, which creates a lag in controlling the future lime quality during the processRealTime Lime Quality Control through Process Shapoorji Pallonji EPC executed A Lime Dolomite Calcination Plant of RMLIII in collaboration with our technology provider Maerz, Switzerland under 7 MTPA expansion of Bhilai Steel Plant by Steel Authority of India Ltd (SAIL) in 2022 We are a diversified business conglomerate with clients in over 50 countries, delivering challenging Lime and Dolomite Calcination Plant at SAIL Bhilai, 2022

(PDF) Management of Lime in Steel ResearchGate

2018年8月31日 The EU28 total lime demand in 2017 was estimated at about 20 million tons, out of which about 40% are consumed in the iron and steel industry2024年1月1日 The cement production industry accounts for up to 15 % of the total industrial energy consumption and produces approximately 5 % of the total anthropogenic CO 2 emissions (IEA, 2019)The basic chemistry of cement production starts with the calcination of limestone (CaCO 3) that produces calcium oxide (CaO) and carbon dioxide (CO 2), followed by the Reducing carbon emissions in cement production through 2021年3月13日 TRAVAUX 49, Proceedings of the 38th International ICSOBA Conference, 16 – 18 November 2020 527 Figure 2 Pyroscrubber and Waste Heat Recovery Boiler Figure 3 SO2 Scrubber and Baghouse 21 SO2 Scrubbing and Byproduct Lime Use The plant uses dry scrubbing technology and requires continuous injection of hydrated limeCB05 Sustainable CPC Production at the Vizag Calciner2020年12月3日 Oona Katajisto COREOona Katajisto CORE

Project Report on LIME CALCINATION PLANT

2023年10月5日 LIME CALCINATION PLANT Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much more If you need any customized project report and BANKABLE project reports as per your requirement, Click here to