Coal Crushing Equment And Mill Design Projects

.jpg)

Research on vertical crusher equipment for coal mining

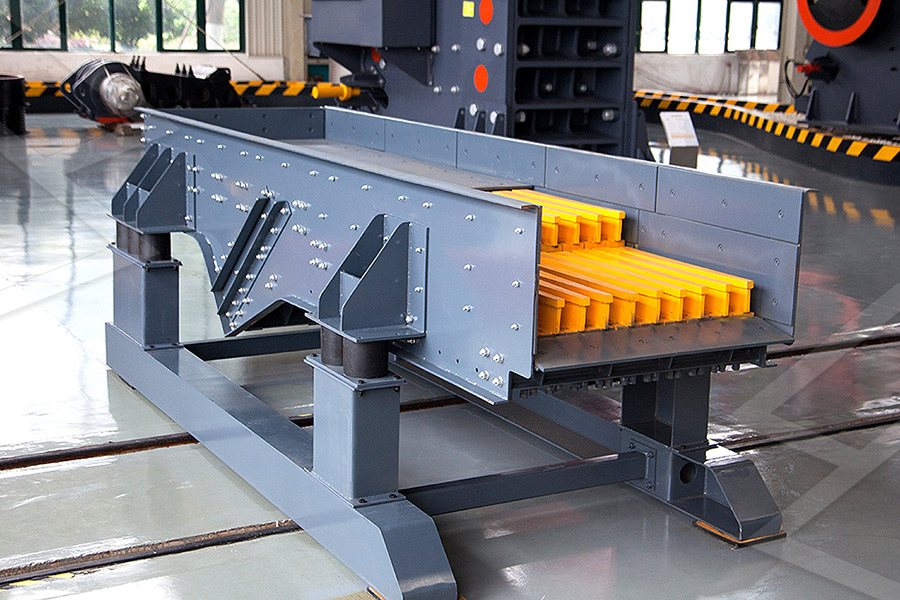

2024年11月12日 Coal crusher is a specialized equipment to crush large coal lumps into the desired size This crushing process helps increase the contact area of coal with air, thereby 2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and Crushing Plant Design and Layout Considerations 911 2024年9月24日 crushing and screening is a most fruitful area for achieving economies in overall mill performance In order to realize how gains can be made, it is necessaryScientific Methods to Design Crushing and Screening 2018年3月19日 Total Coal handling system of JVR CHP is proposed for two streams ie Stream A Stream B Stream A Transportation of G9 Grade coal from Quarry to G/L Bunkers PLANNING, DESIGN, SUPPLY, ERECTION, TESTING AND

.jpg)

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 Coal crushing equipment of coal handling plant system in the thermal power plant is very important for Plant efficiency improvement Keywords: India coal grades, Crusher, 2023年6月30日 Research the modelling and automation of crushing equipment Develop a mathematical model of a cone crusher Identify the effect of plant capacity on the crusher’s current and drive powerModeling and Improving the Efficiency of The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technologySize Reduction of Solids Crushing and Grinding EquipmentThe electric machine builtin roller crusher is an explosionproof electric machine used in the crushing roller Results: Both of these crushers can be used in the selective crushing Recent Patents on Roll Crushing Mills for Selective Crushing of Coal

.jpg)

Design Project of Regenerated Coal RoughCrusher

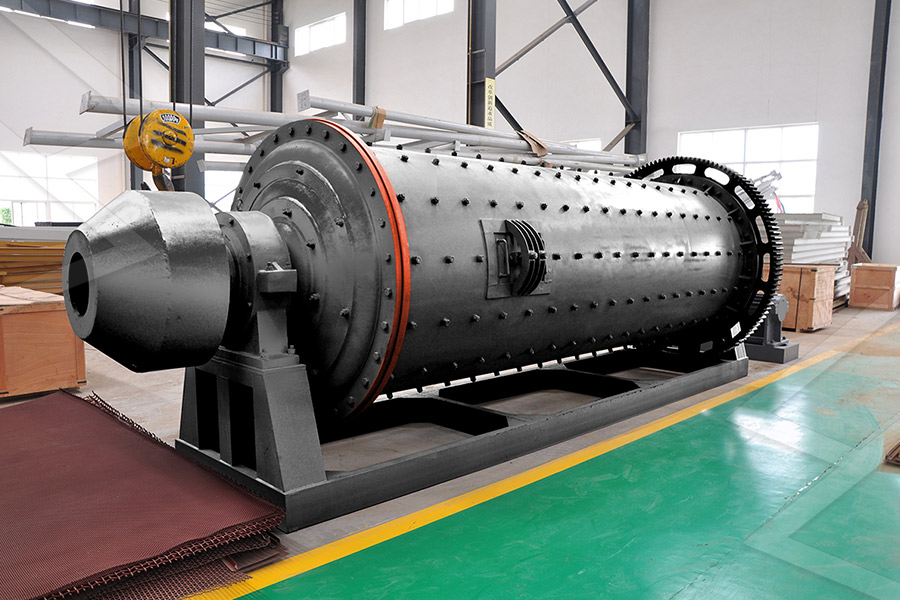

Design Project of Regenerated Coal RoughCrusher Intelligent Control System Based on Image Comparison Abstract: According to the characteristics and requirements of the regenerated 2020年12月1日 DEM models including breakage are capable of simulating industrial scale crushers Compression and impact crushers can be investigated in detail using these models Advanced comminution modelling: Part 1 – Crushers☆Based in Ireland but active around the world, Mills Design is one of most successful design offices of recent years Since 1996 our boats have won many races and regattas around the world, as well as Boat of the Year titles Projects Mills DesignA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics

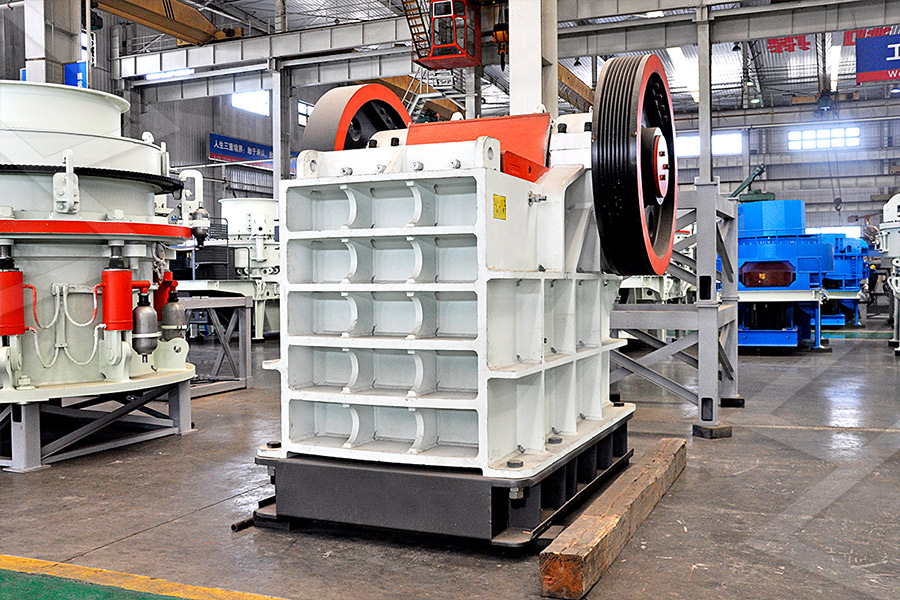

Coal Crushing and Screening Plant – Shalimar Engineering

Shalimar Engineering is a leading manufacturer of coal crushing and screening plants With years of experience in the industry, we have established ourselves as a reliable and efficient provider of highquality machinery Shalimar Engineering specializes in the design and manufacture of coal crushing and screening plants2015年2月25日 The document discusses the history and evolution of coal crushers It begins with an overview of the importance of crushing coal and the early developments starting in the 1800s Key crushers discussed include the Cornish rolls, jaw crushers, gyratory crushers, single and double roll crushers, rotary breakers, impact crushers, and hammer millsCrushing of coal and calculation of size reduction efficiency2018年3月19日 Total Coal handling system of JVR CHP is proposed for two streams ie Stream A Stream B Stream A Transportation of G9 Grade coal from Quarry to G/L Bunkers Stream B Transportation of G12 grade coal from Quarry to washery and washed G 9 grade Coal from washery to G/L Bunkers and in the event of any breakPLANNING, DESIGN, SUPPLY, ERECTION, TESTING AND LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag READ MORE 5X Pendulum Roller Grinding MillStone Crushers, Mill and Grinding

Crusher; Crushing; and Classification Equipment PPT

2020年11月8日 Vertical Shaft Impactors Sandvik is a well established market leader in autogenous VSI crushing The CV200 series offers producers economical and reliable crushing solutions that will result in significant reductions in maintenance with improved health safety considerations Mobile Impact Crusher2024年3月16日 Coal and mill Free download as PDF File (pdf), Text File (txt) or view presentation slides online The document discusses pulverized coal mills used in power plants It describes different types of mills including tube mills, ball mills, and bowl mills Tube mills are low speed while bowl mills are medium speed The document explains the construction, operation, Coal and Mill PDF Mill (Grinding) Mechanical Engineering2024年3月16日 This document describes the design and evaluation of a hammer mill for crushing corn Key points: A hammer mill was designed using computer modeling software to crush corn kernels based on the physical and mechanical properties of corn The hammer mill was tested at different rotor speeds, screen hole diameters, and feeding rates to evaluate Design and Evaluation of Crushing Hammer Mill: January : pradeebhamit@gmail, npappa@rediffmail , vasanthi@annauniv Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill(PDF) Modeling and Control of Coal Mill Academia

.jpg)

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日 The emission factors of kiln end, kiln head, coal mill, crushing and cement mill was 0156 clinker g/t, 3914 clinker g/t, 1538 coal g/t, 0016 stone g/t and 0056 cement g/t respectively, the Stone Crushing Plant With Capacity 350 vertical mill projects, clausing 8530 vertical mill after some cleaning engineering hobbyist projects involving home made vertical roller mill – Quartz CrusherCrush Plant Vertical Mill Projects Crusher MillsConveyor/Crushing Projects Millcreek provided detailed design of a covered twosegment overland conveyor system used to transport 3 million tpy of coal combustion residuals over 7,400 linear feet at 1400 tph from the power plant to the landfill Feeders, stacking equipment, and transfer points were strategically placed to minimize material Conveyor/Crushing Projects Millcreek Engineering2015年4月10日 Based on design criticality, past experience and previous failure information, suitable approach in inspection methodologies can be adopted Maintenance of Coal crushing equipment of coal handling plant system in the thermal power plant is very important for Plant efficiency improvement consist of a crusher followed by a SAG mill followed OPERATION AND MAINTENANCE OF CRUSHER HOUSE

.jpg)

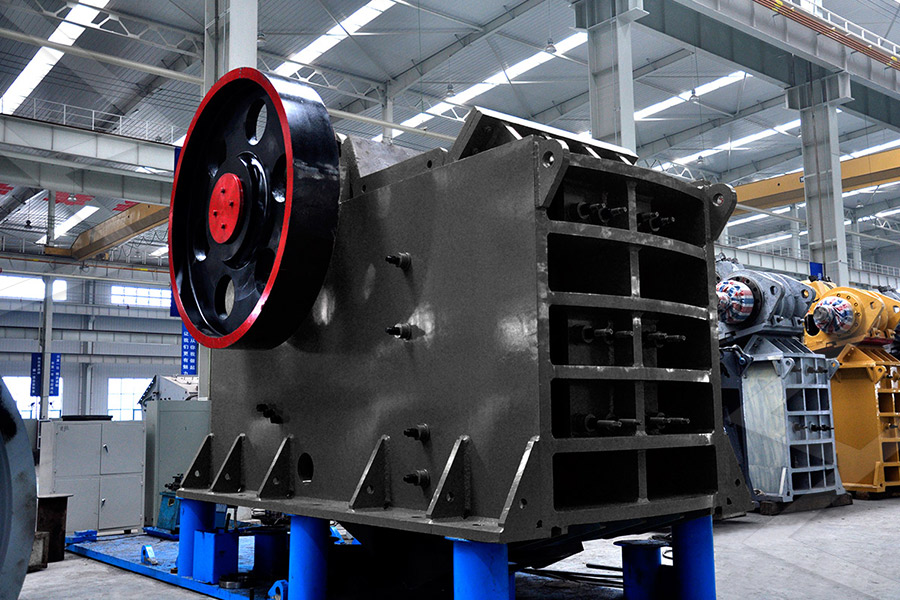

Jaw Crusher or Hammer Mill: Which is Right for Your

2021年11月22日 Jaw crushers and hammer mills used different methods for turning big rocks into small ones, and they are built for their distinct rolls in the reduction process Jaw Crusher Applications Rock crushing often is conducted in stages, with the first process designed to prepare make large chunks of feedstock small enough for a conveyor2009年1月1日 Coal pulverizers play a critical role in the functioning and performance of a PCfired boiler The main functions of a pulverizer are crushing, drying and separating the fine coal particles (PDF) CFD Modeling of MPS Coal Mill for Improved2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and 2023年12月16日 Coal and gas outburst is a dynamic disaster that poses a significant threat to coal mines Energy analysis is an effective tool for understanding the mechanisms behind such outburst The energy sources and dissipation during outbursts were explored using a multifunctional test system, and the energy transformation relationship was analyzed based on Energy Evolution and Coal Crushing Mechanisms Involved in Coal

.jpg)

Jaw Crusher JXSC Machine

2024年11月20日 【Jaw Crusher Parts】Flywheel, pitman, hydraulic cylinder, toggle plate, eccentric shaft, fixed jaw, moving jaw, etc 【Jaw Crusher Working Principle】Motor drive belt and pulley, the eccentric shaft pushes the movable jaw against the fixed jaw, generates the crushing action, compresses the material to the desired sizeThe crushed materials are discharged from The Essa JC1000 Jaw Crusher is the smallest of the range It is a mediumduty, entrylevel machine designed for crushing smaller samples across a wide range of applications Known in the industry as a steadygoing and reliable machine, Laboratory and pilot plant Primary Jaw CrushersDr Li focuses on the application of discrete element methods His recent research interests include bulk coal and rock transportation system, optimized design of mine and agricultural machinery, intelligent coal machine equipment, Engineering Applications of Discrete Element Vertical coal mill is also called LM series vertical roller mill, and is also widely used in mineral grinding mill industry Vertical coal mill is big in appearance with high capacity Raymond Mill is the eary grinding mill, but now is still used widely Coal beneficiation process About Coal Beneficiation, there are three kinds of processes coal crushing and washing plant Grinding Mill China

.jpg)

Coal Crusher Types Impact Double Roller Crusher AIMIX

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal Besides, it is mainly used to crush coal cinder, slag, shale, coal gangue, and other materialsPDF On Sep 1, 2021, Jie Wang and others published Design of Improving Coal Chute in Thermal Power Plant Based on DEM Simulation Technology Find, read and cite all the research you need on Design of Improving Coal Chute in Thermal Power Plant 2015年11月1日 In crushing experiment, a small ball mill was used Firstly, 350 g of coal sample with the particle size of 1–3 cm was loaded in the sample tank In QC anthracite, the addition of water could significantly inhibit CO generation during coal crushing and CO concentration was decreased to 58 ppm after the addition of 60 ml water 32 CO Sources of underground CO: Crushing and ambient2021年7月1日 Vertical stirred mills may be classified according to the speed of the stirrer in two groups: gravityinduced or fluidized mills [[1], [2], [3]]In the gravityinduced mills, the stirrer, generally of the screw type, turns so that the grinding charge exhibits an ascending convective motion at the center, descending from the edges of the screw and close to the mill shell, owing Predicting the effect of operating and design variables in

.jpg)

Coal Pulverizer Design Upgrades to Meet the Demands

2024年8月22日 COAL PULVERIZER DESIGN UPGRADES TO THE DEMANDS OF LOW NOX BURNERS Qingsheng Lin Staff Engineer Fuel Equipment Design Craig Penterson Manager Fuel Equipment Design ABSTRACT Coal pulverizer design and operation is an important element integral to the long term success of Low NOX combustion systems The increased use of Low 2018年12月1日 Coke is one of the most important raw materials for iron making through blast furnace route Strength and reactivity of coke plays a huge role in efficiency of the countercurrent reactorDevelopment of wear resistant hammer heads for coal crushing 2020年1月9日 Geochemical studies of coal mining projects in Environmental Impact Studies (EIS) are often limited to economic characterization of the mineral resource, resulting in a gap in the understanding Recent Patents on Roll Crushing Mills for Selective Crushing of Coal Based in Ireland but active around the world, Mills Design is one of most successful design offices of recent years Since 1996 our boats have won many races and regattas around the world, as well as Boat of the Year titles Projects Mills Design

Coal Mill an overview ScienceDirect Topics

A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Shalimar Engineering is a leading manufacturer of coal crushing and screening plants With years of experience in the industry, we have established ourselves as a reliable and efficient provider of highquality machinery Shalimar Engineering specializes in the design and manufacture of coal crushing and screening plantsCoal Crushing and Screening Plant – Shalimar Engineering2015年2月25日 The document discusses the history and evolution of coal crushers It begins with an overview of the importance of crushing coal and the early developments starting in the 1800s Key crushers discussed include the Cornish rolls, jaw crushers, gyratory crushers, single and double roll crushers, rotary breakers, impact crushers, and hammer millsCrushing of coal and calculation of size reduction efficiency2018年3月19日 Total Coal handling system of JVR CHP is proposed for two streams ie Stream A Stream B Stream A Transportation of G9 Grade coal from Quarry to G/L Bunkers Stream B Transportation of G12 grade coal from Quarry to washery and washed G 9 grade Coal from washery to G/L Bunkers and in the event of any breakPLANNING, DESIGN, SUPPLY, ERECTION, TESTING AND

Stone Crushers, Mill and Grinding

LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag READ MORE 5X Pendulum Roller Grinding Mill2020年11月8日 Vertical Shaft Impactors Sandvik is a well established market leader in autogenous VSI crushing The CV200 series offers producers economical and reliable crushing solutions that will result in significant reductions in maintenance with improved health safety considerations Mobile Impact CrusherCrusher; Crushing; and Classification Equipment PPT2024年3月16日 Coal and mill Free download as PDF File (pdf), Text File (txt) or view presentation slides online The document discusses pulverized coal mills used in power plants It describes different types of mills including tube mills, ball mills, and bowl mills Tube mills are low speed while bowl mills are medium speed The document explains the construction, operation, Coal and Mill PDF Mill (Grinding) Mechanical Engineering2024年3月16日 This document describes the design and evaluation of a hammer mill for crushing corn Key points: A hammer mill was designed using computer modeling software to crush corn kernels based on the physical and mechanical properties of corn The hammer mill was tested at different rotor speeds, screen hole diameters, and feeding rates to evaluate Design and Evaluation of Crushing Hammer Mill: January